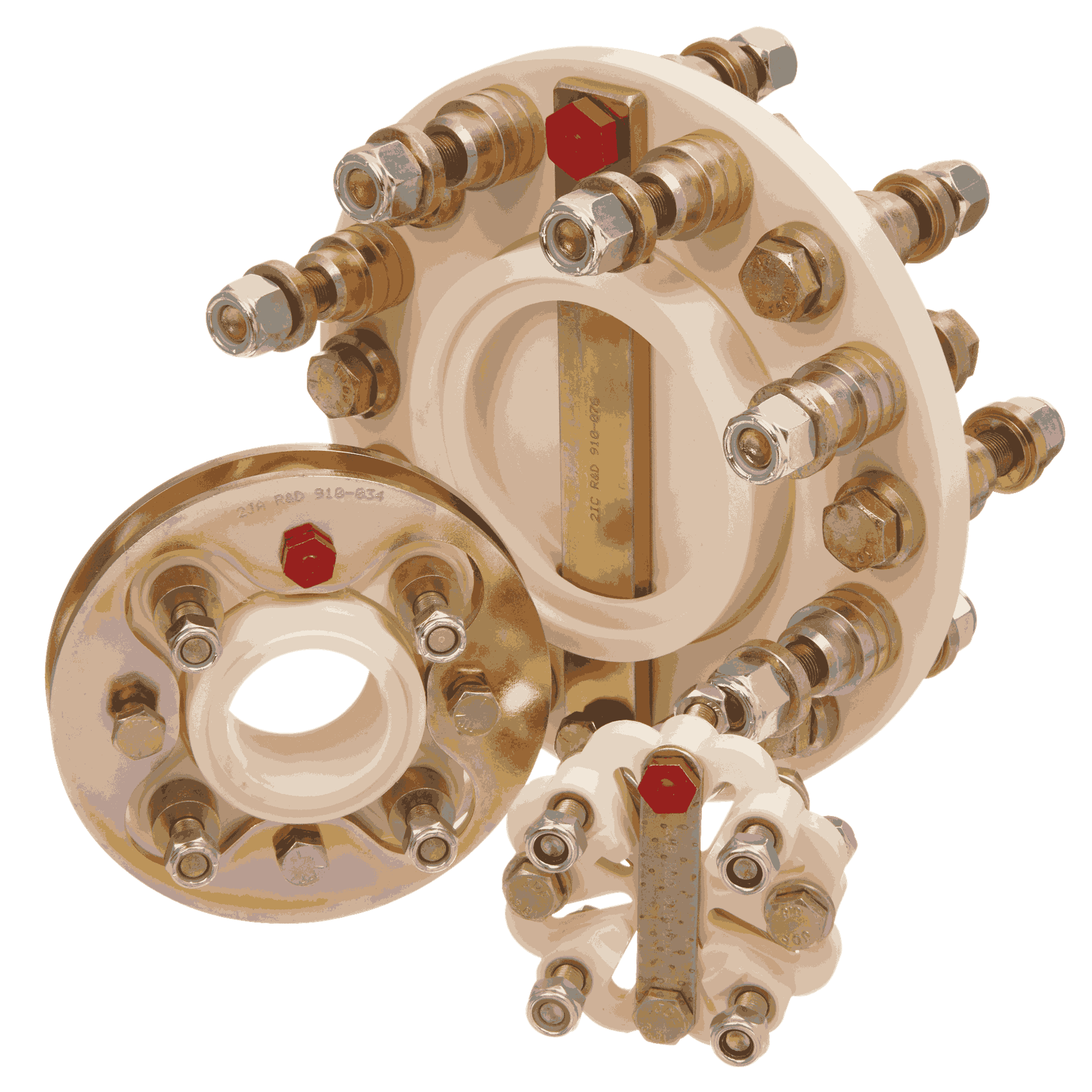

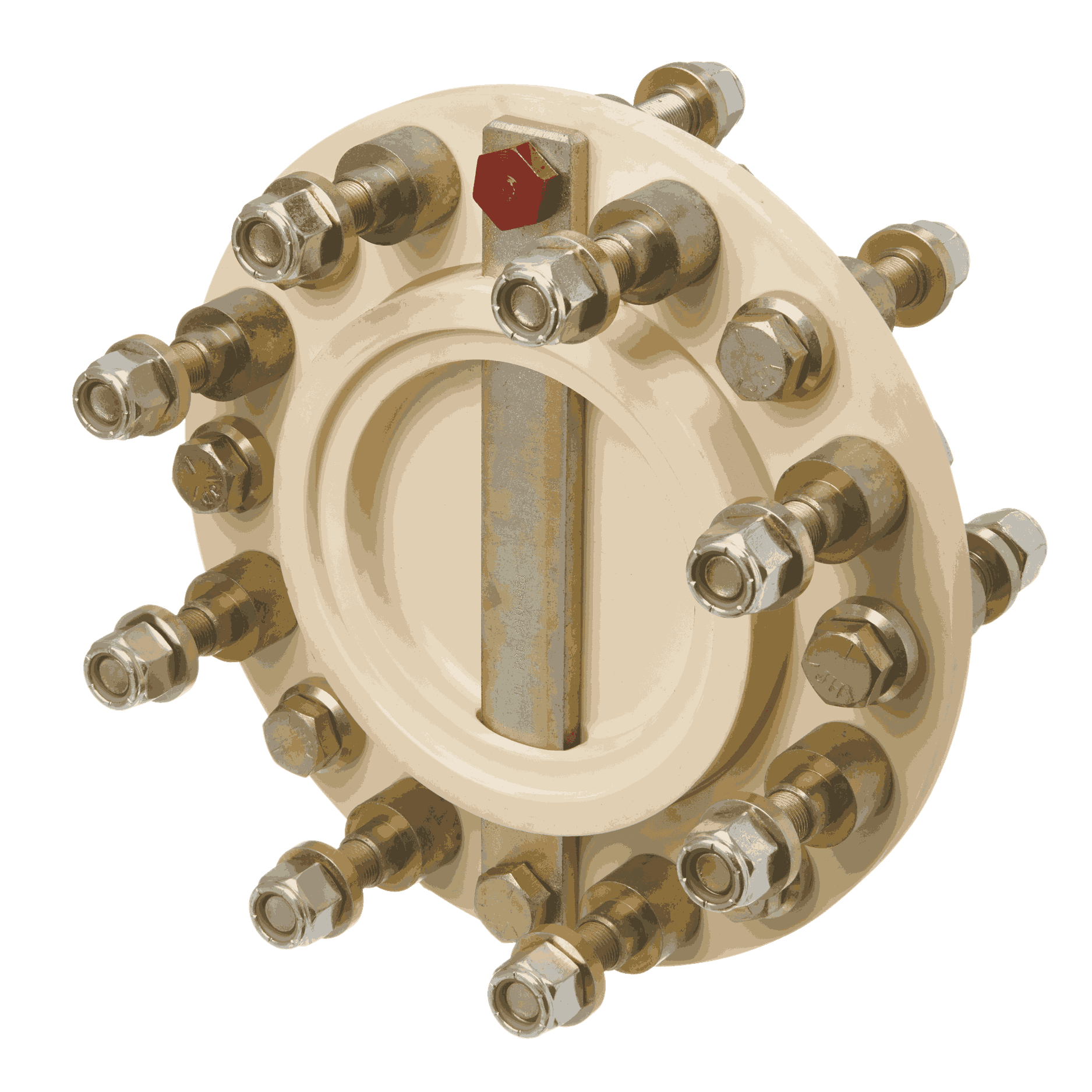

At R&D Marine, we understand the demanding nature of marine environments and the critical role played by reliable power transmission systems. Our flexible shaft couplings are meticulously designed to ensure smooth and efficient operation while mitigating the effects of vibrations, misalignments, and harsh conditions.

Crafted from high-performance polyester elastomer, these couplings exhibit exceptional resistance to saltwater, diesel, and lubrication oils, ensuring long-lasting durability and maintaining their structural integrity in the most challenging marine environments.