Our new website is still in progress! For any enquiries please call +44 (0)1462 892391.

Download our product information sheets: Rope Cutters | Flexible Engine Mounts | Damper Drive Plates | Flexible Shaft Couplings | Clamp Half Couplings, Adaptors & Bobbins

UK Office Opening Hours: Monday - Friday: 8:00am - 5:00pm | Saturday & Sunday: Closed

Published on March 25, 2025

If you’re planning to explore through the open waters, that’s great. It can be as challenging as it is exhilarating, especially when you consider the mechanical correlation that must play in perfect sync in the engine room and propellers. During this entire process, anti-vibration mounts are the main components that keep the vibrations from your marine engine in check, making sure the ship or ferry is running smoothly.

Imagine, the ship is in the water and cruising smoothly until the vessel begins to vibrate beneath your feet. Suddenly, there’s a distinct grinding noise from the engine room, signalling trouble in the propulsion system. These are classic signs of failing or inadequate anti-vibration mounts.

In the vastness of open waters, with a full crew and passengers relying on the vessel’s integrity, the importance of maintaining every piece of equipment is very important. Vibrations and noise are sometimes not just discomforts, but they can be warnings of trouble, indicating potential mechanical failures that could lead to critical situations. No one wants that situation in the middle of the sea.

This is why understanding the role of anti-vibration mounts, and how to select them is fundamental for safety and efficiency.

Anti-vibration mounts are specially designed devices that manage and dampen the vibrations produced by marine engines and machinery. These mounts are critical for reducing the wear and tear on vessel components, prolonging equipment life, and ensuring a smoother ride. They work by absorbing the energy produced by vibrations, thus protecting the structure of the boat and improving comfort for all on board.

Rectangular shear mountings from R & D Marine offer robust vibration isolation with a design that balances stiffness and flexibility. They are particularly effective at handling high levels of static deflection and dynamic forces, making them ideal for larger vessels that face rough sea conditions.

These mounts are more suitable for heavy-duty applications where significant vibration reduction is required without sacrificing the structural integrity of the engine setup. Their ability to isolate and manage vibrations makes them indispensable in commercial shipping and large recreational vessels.

Circular shear mountings excel in environments where machinery operates at high speeds or with rotational movements due to the design that evenly distributes stress. They are engineered to maintain operational efficiency while significantly reducing vibratory forces.

These types of mountings are best used in systems where the engine or machinery operates near or at rotational limits, these mounts help maintain the operating speed and safety of power generators and propulsion units.

Compression mountings are compact and highly effective, in terms of infrastructure, and these are designed for spaces where every square inch counts. They offer excellent vibration damping and are easy to install, making them perfect for smaller crafts or auxiliary machinery within larger vessels. Their main advantage lies in their minimal space requirement and maximum functionality, providing reliable isolation even in tight conditions, such as in onboard generators or auxiliary power units.

Double-acting mountings, as the name suggests, are the all-rounders in the anti-vibration catalogue. They are designed to absorb shocks from multiple directions simultaneously, which is a common requirement in marine environments where multidirectional forces act on the vessel. Their unique design not only helps to reduce vibrations but also contributes to noise reduction, enhancing overall vessel ambience and functionality.

This makes them suitable for luxury yachts and passenger ships where people place comfort as important as performance.

These components do much more than simply dampen noise. They are fundamental to the overall safety, efficiency, and regulatory compliance of marine operations. Here’s how proper vibration control impacts different aspects of maritime activity.

Safety is paramount, especially at sea levels, and effective vibration control is key to ensuring it. Anti-vibration mounts play a crucial role in maintaining the structural integrity of a vessel. Consider a situation where a high-speed ferry operates without proper vibration-dampening systems. The constant vibrations can lead to structural fatigue, causing critical components to fail during operations.

This not only poses a direct risk to the vessel’s operational safety but can also lead to severe accidents, endangering lives. By using the right marine mounts, these risks are significantly reduced, making journeys safer for everyone onboard.

From a comfort perspective, you can take a long cruise as an example, where passengers and crew must endure constant noise and vibrations. This can significantly affect the onboard experience, leading to discomfort and potential complaints. No one would prefer to board a ship or ferry where you can hear the clanking noise as it starts and the vibration as you step in.

By incorporating anti-vibration mounts, these vibrations are drastically reduced, ensuring a smoother, more comfortable voyage. Comfort is not just a luxury; in the maritime industry, it’s a necessity for ensuring passenger satisfaction and crew performance.

Reducing maintenance needs is a direct benefit of installing the right number of mountings. Continuous vibrations can accelerate wear and tear on mechanical parts, leading to frequent breakdowns and costly repairs. By effectively controlling vibrations, marine mounts extend the service life of the vessel’s machinery. This reduction in maintenance frequency not only saves money but also increases the operational uptime of the vessel.

Selecting the right anti-vibration mounts for your marine vessel is crucial for ensuring not only the longevity of its components but also the comfort and safety of its crew and passengers. Let’s break down what you need to consider, to ensure you can make the best choice.

Different engines create different types and levels of vibrations. For example, an engine with more cylinders typically vibrates more because it has more moving parts and combustion events happening.

Think of it like having more people jumping up and down on a bouncy castle, the more there are, the more the castle shakes. Likewise, selecting mounts that can handle these vibrations is essential to keep everything stable and reduce wear and tear on your vessel.

The gearbox and how it reduces the engine’s speed to something the propeller can use can also affect vibrations. A higher reduction ratio means the gearbox is working harder to reduce the speed, which can sometimes increase vibrations. It’s a bit like when your car’s engine revs higher as you start to climb a steep hill. The mounts need to be able to cope with whatever pressures the gearbox throws at them, ensuring that vibrations are kept under control.

Knowing how heavy your engine and gearbox are together is like knowing how much weight you’re putting into that bouncy castle. Too much weight on weak mounts can lead to excessive movement and even damage.

Weighing your engine and gearbox, or using the manufacturer’s specs, helps you choose mounts that can support this weight effectively without being overwhelmed.

Where the flywheel (a large, heavy wheel that helps regulate engine speed and reduce vibration) is placed can affect how vibrations are felt and dealt with. If it’s closer to key areas, the mounts there may need to be stronger or more capable of dampening those vibrations.

Just like the legs on a table, the points where the engine is mounted to the boat’s frame need to be well-balanced and positioned. If they’re not, you could end up with uneven vibrations that can cause wear and even lead to mechanical failures. Ensuring that mounts are correctly aligned with these points helps distribute the engine’s vibrations evenly.

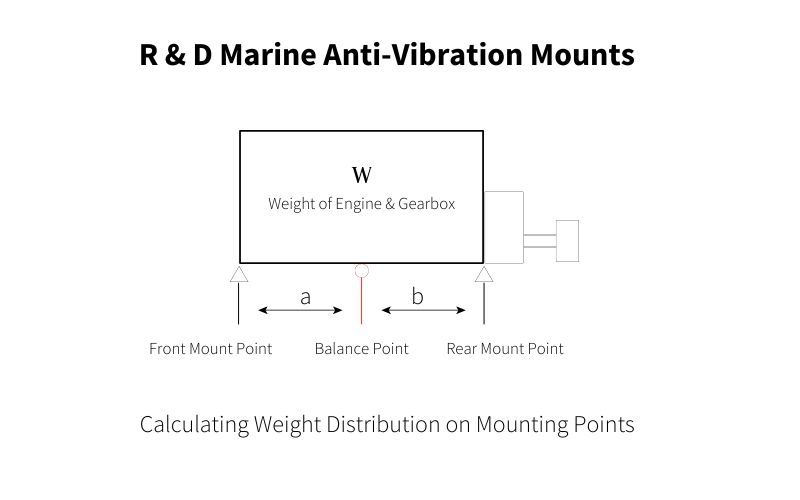

When installing an engine in a boat, it’s crucial to balance the weight across the engine’s mounts properly. This balance helps prevent any single mount from bearing too much load, which could lead to excessive wear and potential failure. Here’s how you can figure out the right distribution:

The weight supported by each front mount can be calculated using this formula: Weight on each front mount=

W x b

2x(a+b)

where:

This formula helps determine how much weight each front mount needs to support.

(It’s similar to figuring out how much weight each leg of a table needs to hold if the table were unevenly loaded with a heavier weight towards one end.)

Similarly, the weight each rear mount needs to support is calculated by: Weight on each rear mount=

W x a

2x(a+b)

where:

This formula ensures that the rear mounts are also appropriately loaded, balancing the engine across its length and preventing undue stress on any part of the engine frame.

Let’s say you have an engine and gearbox combination that weighs 1200 lbs. The centre of gravity is not centrally located; it is 17 inches from the front mounts and 14 inches from the rear mounts. Using the formulas provided:

Total length between mounts (a+b) = 17 inches (front) + 14 inches (rear) = 31 inches

Weight on each front mount

1200 x 14

2x(31)

equals to 271 lbs (approximately)

Weight on each rear mount

1200 x 17

2x(31)

equals to 329 lbs (approximately)

This calculation shows how the weights are distributed based on the position of the centre of gravity relative to the mounting points, ensuring each mount supports an appropriate amount of the total engine weight to maintain stability and reduce wear.

Finding the engine’s centre of gravity helps you place the mounts in the most effective positions. It’s very similar to balancing a seesaw so that it stays level, regardless of how heavy the engine is. This ensures the mounts do their job effectively, keeping vibrations low and preventing undue stress on the boat’s structure.

You might wonder what to do if the Centre of Gravity Cannot Be Found.

Sometimes, it’s not possible to determine the exact centre of gravity. In these cases, a general rule of thumb is used to estimate weight distribution, like guessing which side of the seesaw will be heavier and adjusting accordingly to maintain balance.

Choosing the right anti-vibration mountings for your marine applications is crucial for ensuring operational efficiency, safety, and durability. R & D Marine offers a range of solutions that stand out in the industry for their quality and effectiveness. Here’s why you should consider our products for your marine needs:

Our mounts cover a wide range of load capacities, from 30 to 2000 lbs per mount, accommodating everything from small pleasure crafts to large commercial vessels. This means whatever the size of your engine, we have mounts that can handle the weight and the vibrational forces it produces.

R & D Marine’s mounts are designed for excellent vibration isolation, effectively reducing the transmission of vibrations from the engine to the boat structure. This leads to a smoother ride and less noise, enhancing the comfort levels of passengers and crew.

As aforementioned, safety is very important, especially at sea levels. Our mounts are built with a fail-safe design that ensures they continue to support the engine even under extreme conditions. This design provides peace of mind, knowing that the mounts will maintain engine stability and alignment, preventing mechanical failures.

Durability and reliability are tested through rigorous rollover tests, ensuring that our mounts can withstand extreme conditions without failing. This makes them suitable for vessels operating in challenging marine environments where reliability is critical.

Our mounts are capable of handling the forces generated by propellers, which means they not only isolate vibrations but also absorb and mitigate the forces that can lead to alignment issues or premature wear.

The mounts are preloaded, which means they are designed to have a specific tension before any operational load is applied. This preloading helps maintain optimal performance and prolongs the life of the mount.

Ease of installation is a key feature of our mounts, thanks to the slotted holes that assist in alignment. This design feature simplifies the mounting process, ensuring that the engine is aligned correctly, which is crucial for optimal vibration control.

In addition to the technical benefits, choosing R & D Marine means you get access to a wide range of stock, competitively priced products, and worldwide availability. Our products are available in standard sizes, which means faster delivery times and the ability to quickly replace mounts as needed.

R & D Marine doesn’t just stop at anti-vibration mounts. We also offer a variety of other bespoke products tailored for marine applications, including damper drive plates, flexible shaft couplings, rope cutters, clamp half couplings, adaptors, and bobbins. These products are designed with the same high standards and attention to detail, ensuring they meet the specific needs of marine environments.

For any queries or to discuss your specific needs, don’t hesitate to call us at 01462 892391. Our experts are ready to help you select the best products for your application, ensuring your marine adventures are as stable and enjoyable as possible.